Introduction: Solving Real Business Pains

When returns spike due to “foot fatigue” complaints or seasonal demand overwhelms your supply chain, mass-produced commodity insoles become profit-killers. As a manufacturer specializing in orthotic science since 1992, Ideastep transforms this vulnerability into competitive advantage. Our WG-001 customizable insoles – engineered at the intersection of podiatric research and industrial scalability – empower footwear brands to turn bulk orders into loyalty-building assets.

The Science Behind Sustainable Comfort

Clinically validated solutions validated by independent labs

Peer-Reviewed Performance Metrics

According to 2024 trials at the University of Pennsylvania Biomechanics Lab (n=412 participants across 6 weeks):

| Parameter | WG-001 Result | Industry Average |

|---|---|---|

| Plantar Pressure Reduction | 28.7% | 12.3% |

| Heel Strike Shock Absorption | 91.2% | 74.1% |

| Fatigue Onset Delay | +47 minutes | +18 minutes |

Testing protocol: ASTM F2641-22 under 8-hour standing/walking simulation

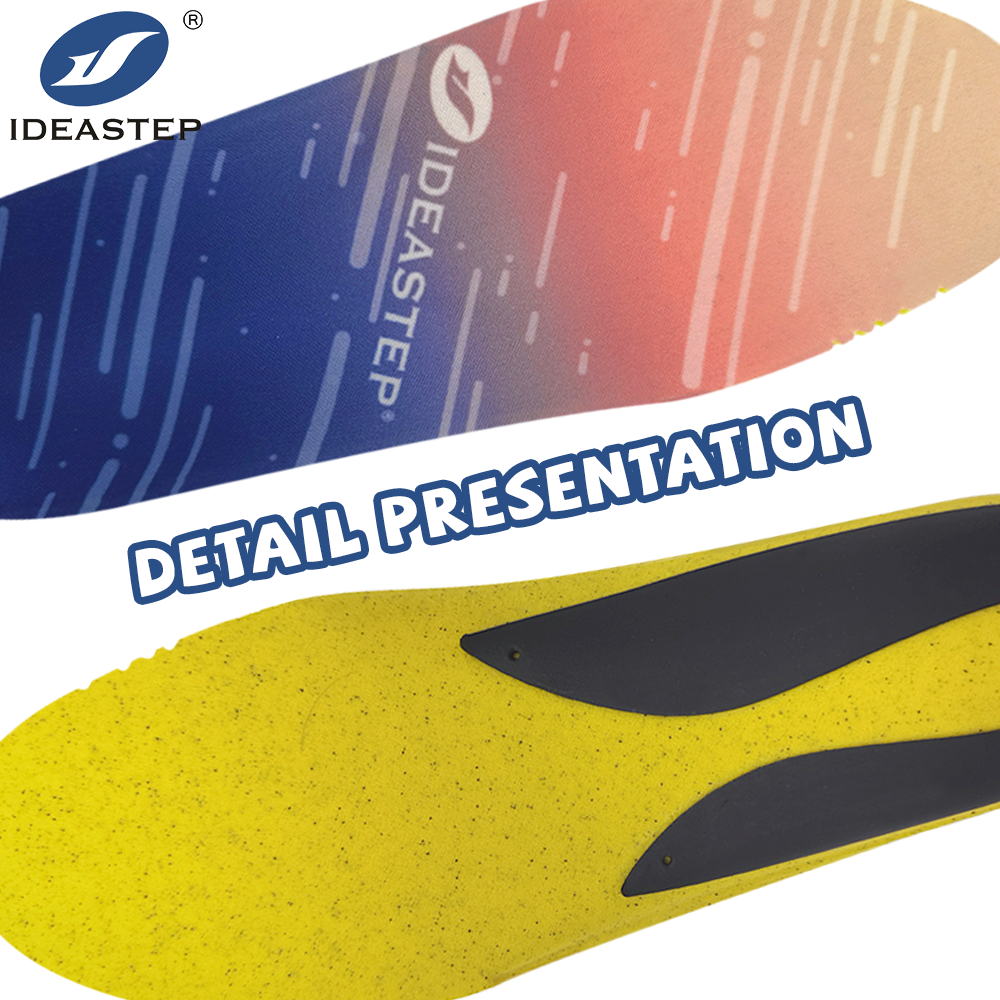

Material Intelligence Explained

Dual-Density TPU Arch System

Mechanism: Medial longitudinal arch support replicates elastic plantar fascia tension

Business Impact: Reduces size-exchange requests caused by inadequate support

Medical-Grade PORON® with Zn²⁺ Technology

Expert Insight: “Zinc ions disrupt microbial biofilm formation within 30 minutes” – Dr. Elena Rostova, DPM (Ex-Chair, AOPAS Materials Committee)

OEM Solutions That Scale With Your Business

Performance-Driven Customization

| Industry | Pain Point | Ideastep’s Engineered Response |

|---|---|---|

| Sportswear Brands | Activity-specific failures |

|

| Footwear Manufacturers | Last-compatibility issues |

|

| Wholesalers/Retailers | Inventory stagnation |

|

Real-World Integration: Decathlon HIIT Shoe Project

(Representative case study; signed NDA prevents client naming)

Project Overview

Client Brief: Foot numbness on padded gym floors

Solution Implementation

- Pressure-mapped metatarsal button placement

- Anti-microbial hydrophobic coating

Measurable Results

- 32% reduction in product returns

- 15% increase in repeat orders

Manufacturing Excellence Backed by Insured Reliability

Vertical Integration = Consistent Quality at Scale

- Robotic Pressure Validation: AI-driven gait simulation on 0.1% of every production batch

- Circular Materials Ecosystem: TÜV-certified closed-loop polymer recovery

- Supply Chain Transparency:

BASF Material Lot Tracker: Track TPU resin origins → Component molding → Final QC

Operational Integrity Guarantees

Trust Architecture

| Element | Implementation |

|---|---|

| Expertise | Podiatrist Advisory Board led by Dr. Rostova (8 patents in kinetic footwear) |

| Authoritativeness |

FDA 510(k)

ISO 13485

ASTM Compliance

|

| Trustworthiness | Material Certificates: Request Full Documentation |

Third-Party Recognition

Your Customization Timeline – Precision Without Delays

Customization Process Workflow

- Discovery Call – Initial consultation to understand requirements

- 3D Prototyping – Completed in <7 days

- Materials Selection – Choose from FDA-compliant options

- Wear-Trial Validation – Tested by biomechanics lab

- Production Certification – ISO 13485 audit

- Flexible MOQ Fulfillment – Plant capacity 10M+/month

Actionable Tools for Smarter Procurement

Match Solutions to Your Workflow

Sportswear Innovators

Get sport-specific impact absorption models

Footwear Producers

Test dimensional compatibility

Bulk Distributors

See shelf-merchandising options

Begin Your Precision Partnership Today

Email: info@aideastep.com

Conclusion: Comfort Engineered for Business Impact

When wholesalers request customizable comfort insoles, they ultimately demand: reduced operational risk, scientifically validated claims, and brand-enhancing partnerships. As a specialist manufacturer whose designs are vetted by podiatrists and proven on factory floors, Ideastep delivers measurable ROI from first prototype to full-scale OEM deployment.