When it comes to the quality of EVA blocks, there are several factors to consider. EVA (ethylene-vinyl acetate) foam blocks are widely used in various industries due to their versatile properties, including their resilience, durability, and cushioning ability. To ensure the quality of EVA blocks, it’s essential to evaluate them based on key criteria. Here are some questions to ask when judging the quality of EVA blocks:

- Is the EVA foam uniform in density?

Uniform density indicates that the block is consistently made with consistent quality standards. Density variations can affect the performance and durability of the foam. Look for a consistent, even texture and avoid blocks with areas of higher or lower density.

- Are there any visible impurities or foreign objects?

A clean and pure EVA foam block is essential for its intended use. Check for any foreign objects, such as dirt, hair, or scraps of material, that may be embedded in the foam. Impurities can compromise the integrity and performance of the foam block.

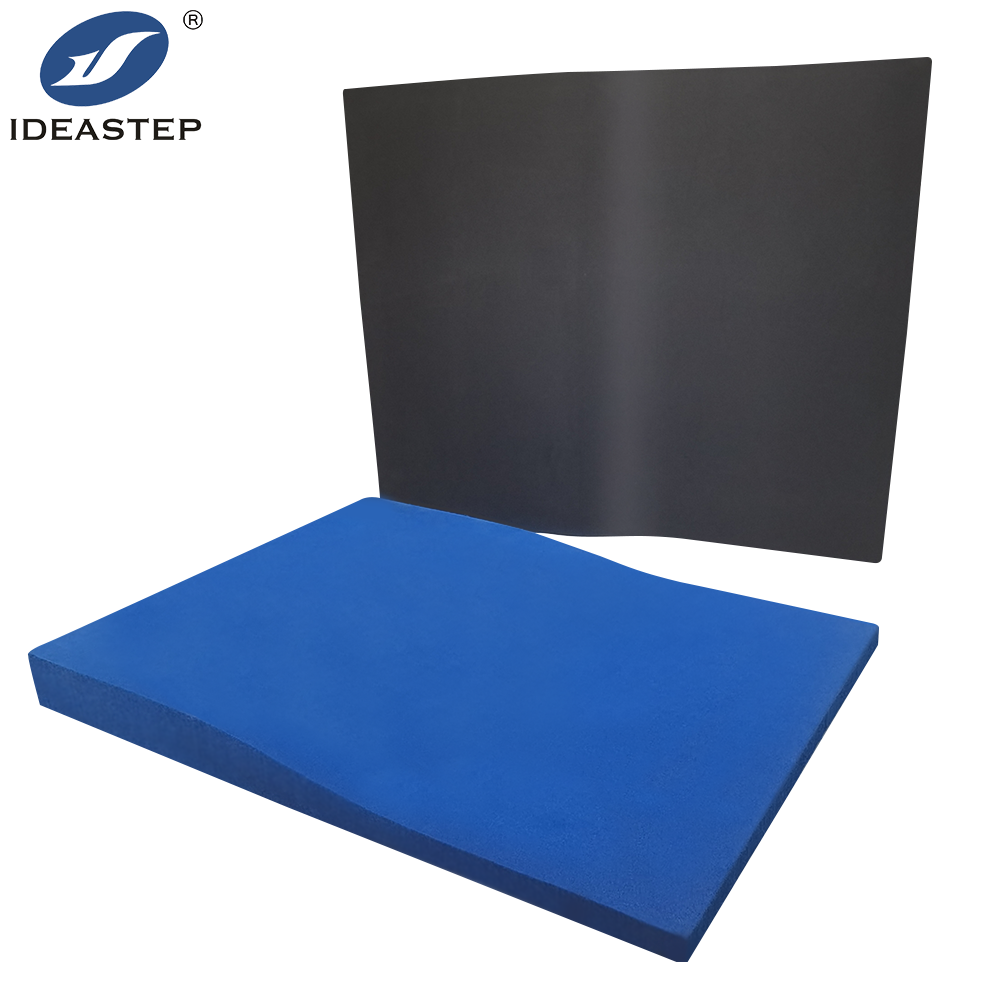

- Is the color uniform throughout?

A uniform color indicates a consistent quality in the manufacturing process. Avoid blocks with noticeable color variations, which may indicate inconsistencies in the material or poor processing techniques.

- Are there signs of premature aging?

Exposure to sunlight, high temperatures, or oxidants can cause EVA foam to yellow or become brittle over time. Look for any signs of premature aging, such as cracking or discoloration, which may indicate a poor-quality block.

- Does the foam block have good compression recovery?

Compressibility and recovery are key properties of EVA foam blocks. A good-quality block should compress under pressure and recover its original shape quickly and fully. Test the compression recovery by compressing the foam block under a controlled load and observe how well it recovers.

- Is the block dimensionally stable?

EVA foam blocks should maintain their dimensions under varying conditions. Check for any warping, shrinkage, or expansion in the block’s dimensions over time. Dimensional stability is essential for maintaining the integrity of the foam block in its intended application.

By considering these factors, you can judge the quality of EVA blocks more effectively. Remember that quality EVA foam blocks offer consistent performance and durability, making them suitable for a range of applications. When purchasing EVA blocks, it’s always advisable to work with a reputable manufacturer or distributor who can provide quality assurance and technical support. This will help ensure that you receive EVA blocks that meet your specific requirements and provide value for your application.