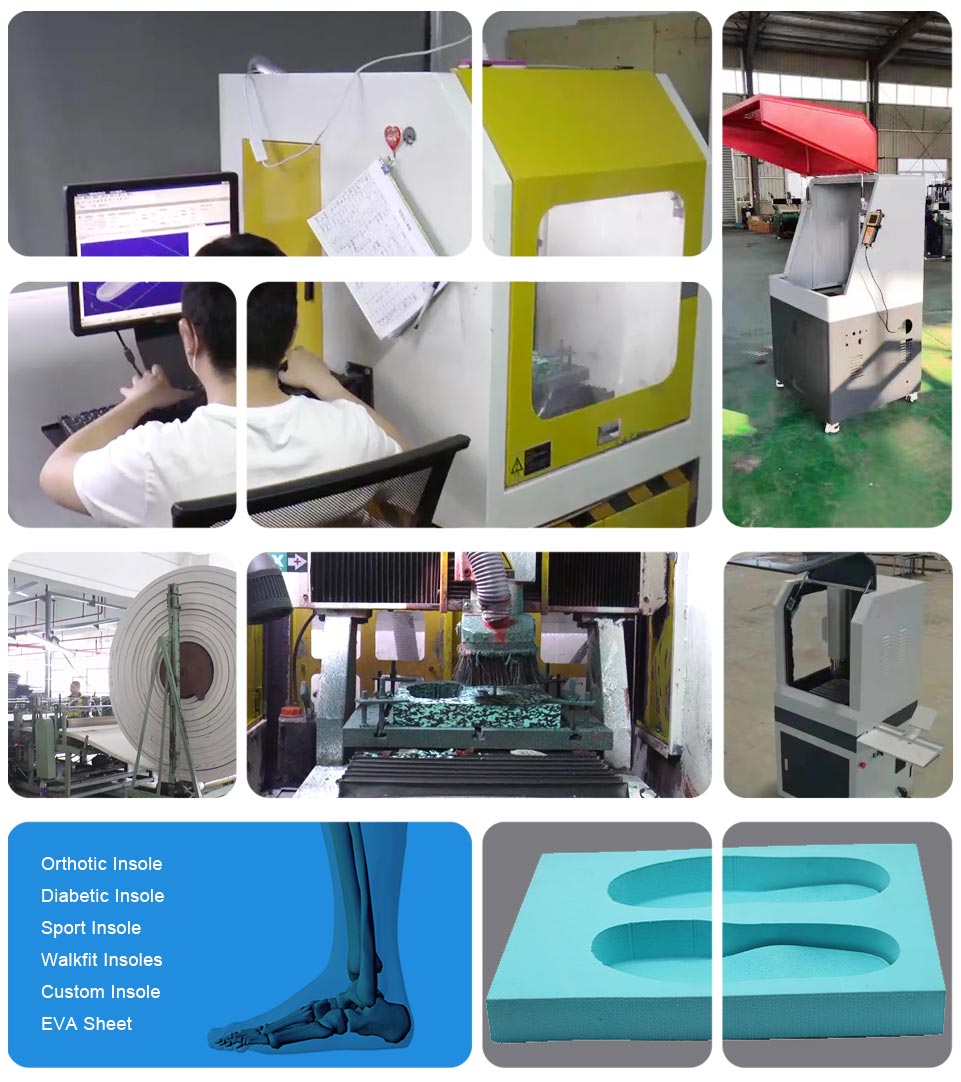

Ideastep adhesive eva foam sheets goes through a series of production processes: grouting, demoulding, splicing, drilling holes, glaze spraying, and firing which are all carried out by professional workers. It is made based on the real person picture or drawing

We mainly customize insoles and EVA sheets. We have leading technology and advanced production equipment, focus on the insole field for more than 20 years, and have the American Medical Council Certification Committee "C.Ped. #4290

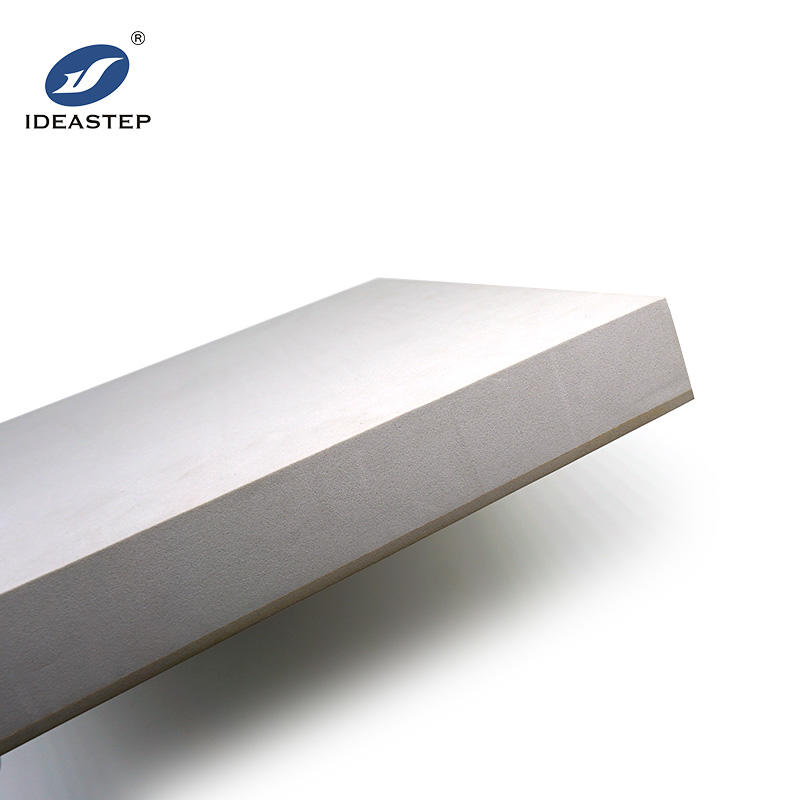

| Type | EVA |

| Brand Name | IDEASTEP |

| Place of Origin | XIAMEN ,Fujian, China |

| Model No. | KE13# |

| Size | 30*38*3.8cm or customized |

| Color | Grey or customized |

| Material | EVA |

| Package | As per requirement |

| MOQ | 1000 Pairs |

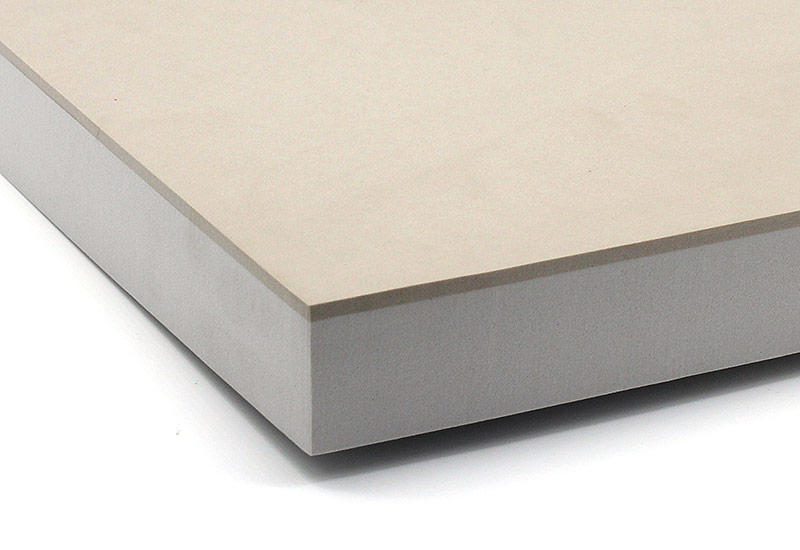

| Feature | Two different Eva materials combinated |

Dual densities of EVA, 4mm 45/50A+ 34mm 55/60A

Ideal for CNC milling for custom made Orthotic insole material.

|

◪ The double Densities Eva in a glued combination |

|

◪ The quality EVA provide permanent resilience and stabilisation base |

Q1: What’s this Eva Block used for?

A1: this Eva Block is the basis for the manufacture of foot beddings and inserts in orthopaedic shoe engineering.

Q2: What’s the most benefit of this CNC eva foam?

A2: It’s outstanding edge stability for pressed insoles and has excellent grinding and bonding properties

Q3: Could I change the hardness?

A3: Yes, EVA hardness can be changed according to your needs.

Q4: Could I get single,dual and triple layers for this kind Eva Block?

A4: Yes, the different layeres can be satisfied

Q5: What’s the areas of application for this kind Eva Foam block?

A5: It’s good for rheumatism, geriatric foot, diabetes, and a basis for sports inserts