3D CAD/CAM EVA Milling Orthotics

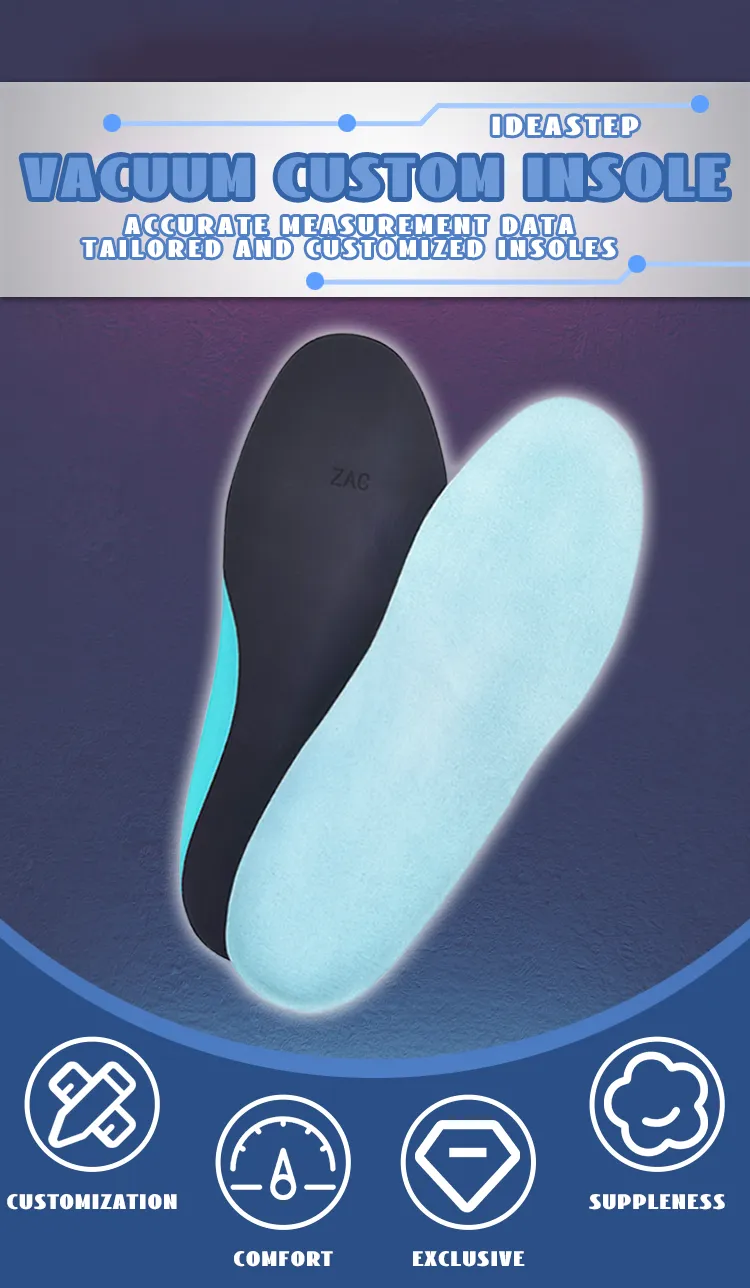

Based on cutting-edge technology and innovative methods, our product revolutionizes the field of podiatry by offering a highly personalized and effective solution for correcting foot issues. By leveraging the data obtained from detailed foot scans and utilizing state-of-the-art design software tools, we are able to create a customized and precise foot shape that aligns with the podiatrist’s treatment goals.

Through a meticulous process that involves analyzing and interpreting the scanned foot data, we can accurately capture the unique characteristics of the patient’s foot. This data serves as the foundation for tailoring the foot shape to address specific concerns and optimize correction results. The flexibility and adaptability of our design software tools enable us to make precise adjustments that meet the individual needs of each patient, ensuring a perfect fit and maximum comfort.

Our approach involves using 3D foot scan data for modeling and production purposes, allowing us to create detailed and accurate representations of the patient’s foot shape. Additionally, we employ foot last scans to replicate and refine the design, ensuring a seamless and precise fit for the patient. By combining these two methods, we can achieve the ideal correction effect that enhances the patient’s foot health and overall well-being.

Our product offers a comprehensive and tailored solution for podiatrists seeking to provide their patients with the best possible care. Through the integration of advanced technology, detailed foot scans, and precise design tools, we are able to deliver exceptional results that meet the unique needs of each individual.

Production process:

- Data Collection and Analysis:

- Utilize a scanner to collect detailed foot data and conduct a comprehensive analysis to understand the specific foot shape and requirements.

- Online Prescription Submission:

- Transmit the analyzed data and prescriptions efficiently through online platforms, enabling seamless communication between podiatrists and manufacturers.

- 3D CAM Modeling and Design:

- Employ advanced 3D Computer-Aided Manufacturing (CAM) software to create precise models and develop personalized orthotic designs tailored to the patient’s needs.

- Custom Insole Manufacture:

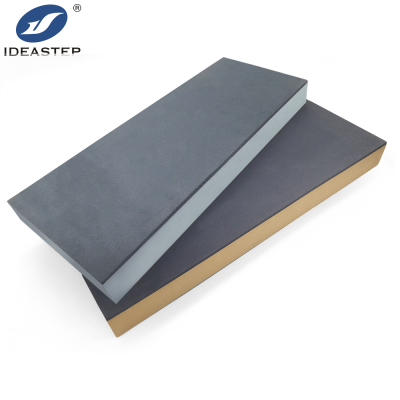

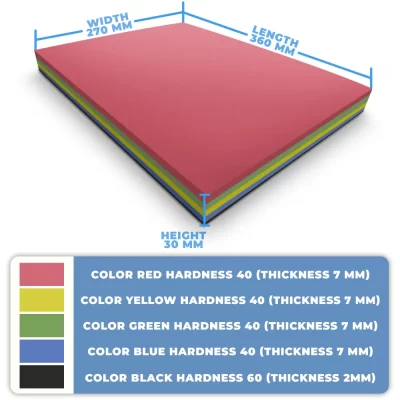

- Utilize Computer Numerical Control (CNC) technology to manufacture custom insoles by milling high-density EVA blocks with exceptional accuracy and consistency.

- Efficient Delivery Service:

- Ensure prompt and efficient delivery of the custom-made insoles to the podiatrist or patient, maintaining the quality and integrity of the product throughout the shipping process.