The hardness value of EVA block is a crucial factor that determines its suitability for various applications. EVA foam, or ethylene-vinyl acetate foam, is a versatile material that offers a range of properties, including its hardness. The hardness of EVA foam is measured using the Shore A scale, which ranges from Shore A 0 (softest) to Shore A 100 (hardest).

When it comes to the hardness value of EVA block, there are several considerations to keep in mind:

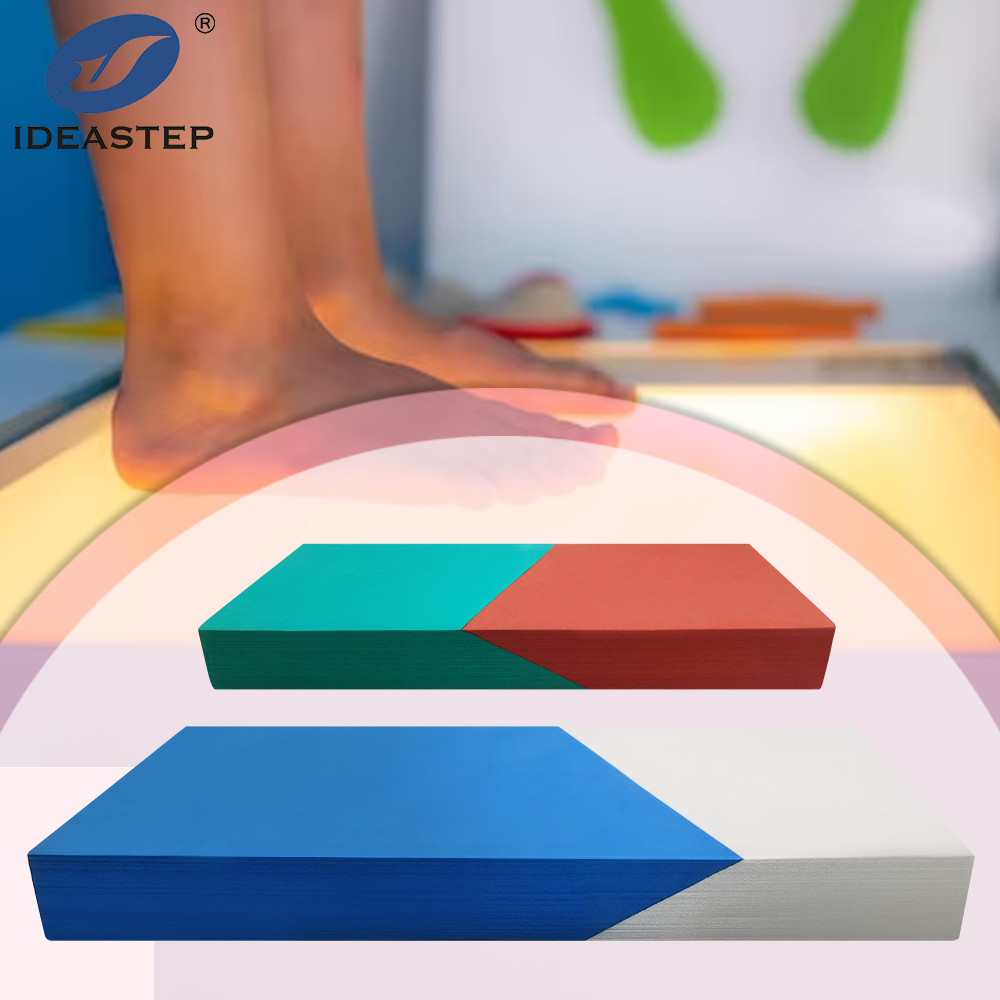

Application Requirements: The hardness of EVA foam blocks is determined by the specific application requirements. Different industries require EVA foam blocks with different hardness levels. For example, footwear manufacturers may prefer a softer EVA foam block for comfort, while packaging industries may require a harder block for support and cushioning.

Density: The density of EVA foam also plays a role in its hardness. A higher density foam will typically exhibit a harder feel, while lower density foam will be softer. Density can be adjusted during the manufacturing process to achieve the desired hardness level.

Manufacturing Process: The manufacturing process of EVA foam blocks can affect their hardness. The crosslinking process and the use of blowing agents during production can influence the final hardness of the foam. Controlled processing conditions can help to ensure consistent hardness levels in EVA foam blocks.

Additives: Additives such as stabilizers, colorants, and other modifiers can have an impact on the hardness of EVA foam blocks. These additives may be added to modify the physical properties of the foam, including its hardness.

Temperature and UV Exposure: EVA foam blocks may experience changes in their hardness over time due to exposure to temperature and UV rays. Prolonged exposure to high temperatures or UV light can cause the foam to soften, altering its original hardness value.

It’s important to note that the hardness value of EVA block is not the only factor to consider when selecting the appropriate foam for your application. Other factors such as compressibility, resilience, and durability should also be taken into account.

In conclusion, the hardness value of EVA block depends on several factors, including application requirements, density, manufacturing process, additives, temperature, and UV exposure. Understanding these factors is crucial when selecting the appropriate EVA foam block for your specific needs. Contact a manufacturer or distributor who can provide more information on the hardness levels available for EVA foam blocks and recommend the most suitable option for your application.