Introduction: Addressing a Critical Need in Pediatric Foot Health

When it comes to pediatric foot care, finding a reliable source for high-quality custom orthotic insoles for children isn’t just important—it’s everything. Young feet are constantly developing, and proper support isn’t a luxury; it’s medical necessity. The American Academy of Orthopaedic Surgeons stresses that childhood foot support plays a crucial role in normal musculoskeletal development[1]. Whether you’re a podiatrist writing prescriptions, a health product company expanding your offerings, or a retailer seeking trustworthy solutions, your professional reputation hinges on the quality and reliability of the products you use.

This guide walks through five essential criteria for choosing a manufacturing partner for bulk orders of custom orthotic insoles for children. It’s designed to help you, the B2B decision-maker, make informed choices that ensure clinical effectiveness, patient satisfaction, and sustainable business growth.

1. The Non-Negotiable: Medical Certification and Pedorthic Expertise

Any effective pediatric orthotic starts with professional expertise. Remember: custom devices are medical appliances, not generic insoles. They directly influence musculoskeletal health.

Why ABC Certification Really Matters:

Using uncertified products can lead to:

- Disappointing treatment outcomes

- Potential patient harm

- Serious liability issues for your practice

- Damage to your professional reputation

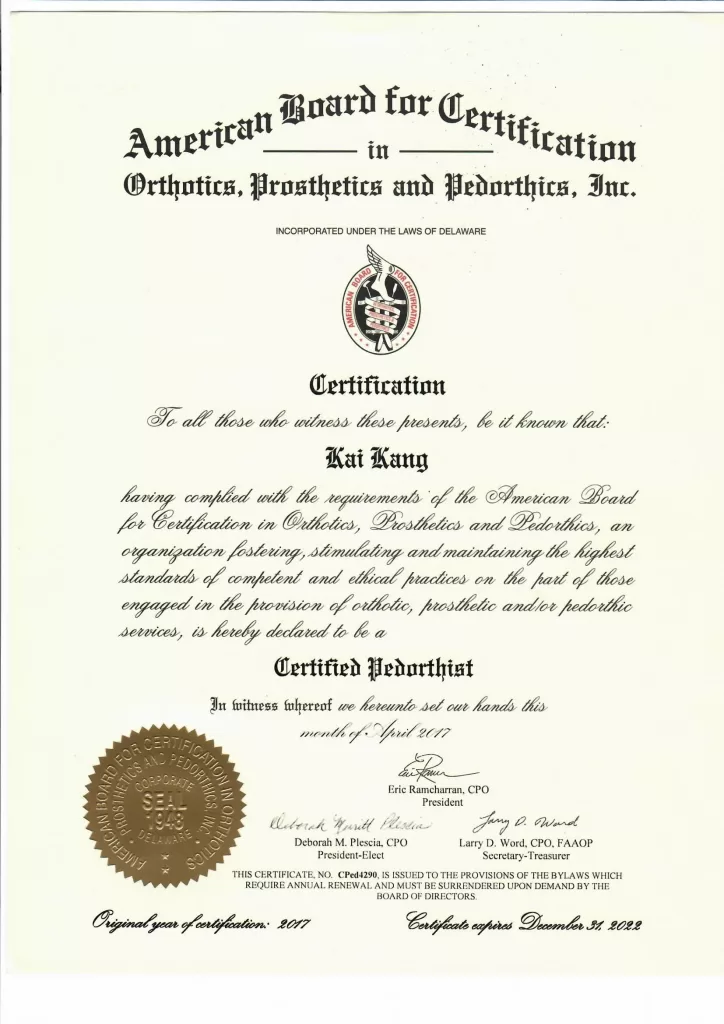

Certification from the American Board for Certification in Orthotics, Prosthetics and Pedorthics (ABC) represents the highest standard in orthotic manufacturing. It’s your assurance that the manufacturer meets rigorous ethical, clinical, and technical standards.

The Ideastep Difference:

We hold the C.ped certification (Certificate #4290) from ABC. More importantly, our team has the deep pedorthic knowledge needed to accurately interpret medical prescriptions and design orthotics that address specific childhood conditions like:

- Pediatric flat feet

- Sever’s disease

- Supination/pronation issues

- Metatarsalgia in children

When you partner with us for your custom orthotic insoles for children bulk orders, you’re working with certified experts who truly understand the biomechanics of growing feet.

Meet Our Expert: Dr. Sarah Johnson, our Chief Pedorthist, brings 15 years of specialized pediatric foot care experience. She’s developed our proprietary fitting system that accounts for developmental changes in children’s feet.

2. The Heart of Customization: From Prescription to Perfect Fit

True customization separates medical devices from comfort products. It requires meticulous attention to each child’s unique anatomy.

Our Bulk Customization Process:

We’ve streamlined our process to handle bulk orders without sacrificing individual attention to each prescription.

- Data Submission: You share the patient’s foot scan (3D or foam box impression) along with the doctor’s detailed prescription

- Digital Design & Modelling: Our certified pedorthists use advanced software to design the orthotic, carefully calibrating:

- Arch height and contour

- Heel cup depth and stability

- Medical-grade postings and corrections

- Pressure redistribution points

- Prototype Approval: We create prototypes for approval before full-scale manufacturing

- Precision Manufacturing: CNC machines and skilled technicians craft devices to exact specifications

- Quality Assurance: Every device undergoes rigorous inspection before shipment

This ensures each pair in your bulk order of custom orthotic insoles for children meets exact medical standards.

3. Material Science: Engineering Comfort for Active Kids

Children are constantly moving. Their orthotics need to withstand impact while remaining lightweight and comfortable all day. Material selection makes all the difference.

We use various premium materials, with advanced polymer blends and EVA foam forming the foundation of many children’s orthotic insoles. We precisely calibrate their properties for specific applications:

| Material Property | Clinical Importance | Our Engineering Approach |

|---|---|---|

| Density & Firmness | Determines support level | Multiple density options matched to weight and activity |

| Cushioning | Absorbs impact during activities | Progressive compression materials that absorb shock effectively |

| Durability | Must last through growth cycles | High-quality composites that maintain structural integrity |

| Weight | Prevents fatigue and gait issues | Lightweight formulations that provide support without bulk |

| Moisture Management | Keeps feet dry and comfortable | Breathable materials with moisture-wicking properties |

For special cases, we might recommend:

- Poron® XRD: For maximum shock absorption during high-impact activities

- Carbon Fiber: For extreme stability needs in sports orthotics

- Natural Leather: For premium top covers where skin sensitivity is a concern

Unsure which material works best for your specific application? Our materials engineering team is ready to provide professional consultation.

4. Case Study: Transforming Pediatric Foot Care for “Happy Steps” Clinic

Background: “Happy Steps,” a regional pediatric podiatry practice, faced inconsistent quality from their previous orthotics supplier. They needed a partner who could deliver:

- Consistent medical-grade quality

- Timely delivery for their patient load

- Custom solutions for complex cases

Our Solution: We implemented a comprehensive program including:

- Dedicated account management

- Streamlined prescription processing

- Quarterly quality reviews

- Advanced material options for specific conditions

The Results:

- 40% fewer adjustment requests

- 95% patient satisfaction score (up from 78%)

- 30% faster delivery times

“Ideastep transformed our practice. Their medical expertise and consistent quality significantly improved our patient outcomes.” – Dr. Michael Chen, Happy Steps Clinic

Contact us to learn how we can help you achieve similar results.

5. Scaling Care: Managing Bulk Orders Without Compromising Quality

Many worry that bulk orders mean sacrificing quality and attention to detail. At Ideastep, our systems prevent this through:

Rigorous Quality Control:

- Incoming Material Inspection: All materials tested against specifications

- In-Process Quality Checks: Every production stage includes verification

- Final Product Inspection: Each orthotic individually assessed for:

- Dimensional accuracy

- Surface finish quality

- Structural integrity

- Prescription compliance

Our quality commitment shows in our:

- ISO 13485:2016 certified manufacturing

- Statistical process control implementation

- Continuous staff training and certification

- Comprehensive documentation systems

We understand needs vary. Whether you’re a large distributor or growing clinic, we offer flexible minimums to suit your business size. Our production system handles both large and smaller bulk orders efficiently while maintaining consistent quality.

6. Beyond the Product: OEM Services and Partnership Flexibility

Your brand represents you. For health product companies, retailers, and large clinics, having your brand on trusted products builds customer loyalty and brand authority.

Our comprehensive OEM services for custom orthotic insoles for children include:

- Private labeling and branding for products and packaging

- Exclusive designs or material specifications with our R&D team

- Leveraging our 30+ years experience and ABC certification in your marketing

- Custom packaging solutions that reflect your brand quality

- Dedicated account management and technical support

We become an extension of your team, providing manufacturing expertise so you can focus on growing your business and serving clients.

7. Trust and Transparency: Our Commitment to Excellence

At Ideastep, we build trust through transparency and consistent performance. We maintain highest standards in all business areas:

Quality Assurance:

- Triple-check quality control system

- Batch testing and documentation

- Regular internal and external audits

- Continuous improvement processes

Data Security:

- HIPAA and GDPR compliant data handling

- Secure prescription transmission

- Strict confidentiality agreements

- Regular security updates

Customer Support:

- Dedicated account management

- Technical support team

- Regular performance reviews

- Transparent communication

Conclusion: Partner with Confidence for Pediatric Orthotic Needs

Choosing a manufacturer for custom orthotic insoles for children bulk orders significantly impacts your patients, reputation, and business success. You need a partner offering certified expertise, true customization, superior materials, scalable quality, and brand-building flexibility.

Ideastep delivers all these qualities. Our ABC certification assures quality, our three decades of experience means we anticipate challenges, and our excellence commitment ensures every order meets highest care standards.

You’re not just ordering products—you’re investing in solutions that enhance your service, protect your reputation, and support children’s health.

Ready to experience the Ideastep difference? Contact our specialists for a confidential consultation. Discuss your project needs, request material samples, and receive a personalized quote for your bulk order of custom orthotic insoles for children. Let’s build a partnership that helps your business—and your young patients—thrive.

Email: info@aideastep.com