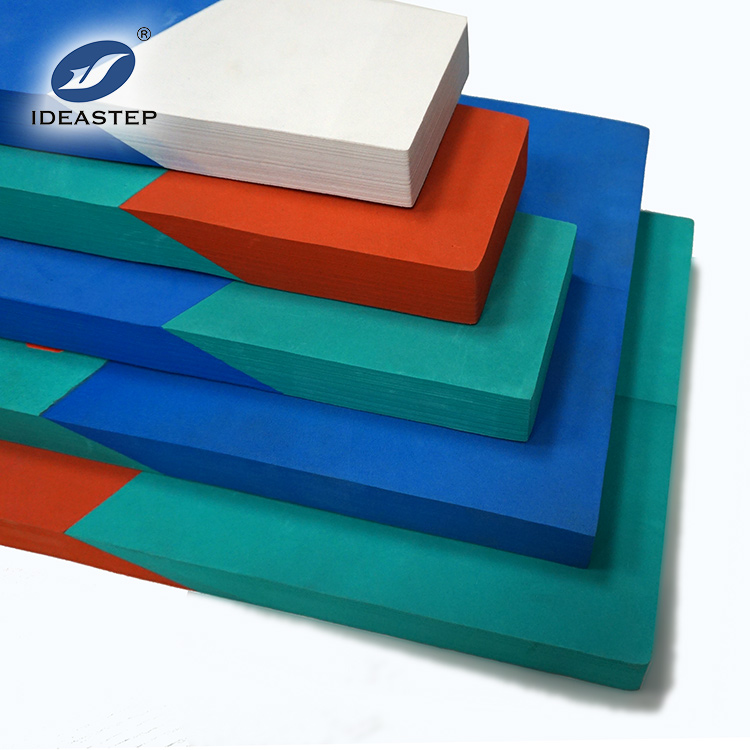

In the modern society that pursues high-performance materials, high-elastic EVA Block has received widespread attention for its excellent elasticity and durability. This material not only has excellent resilience, but also has outstanding physical and mechanical properties, making it suitable for various application fields that require high elasticity. This article will give a detailed introduction to the material selection, manufacturing process, production process, characteristics and application fields of high-elastic EVA Block, and provide readers with a comprehensive and true reference based on relevant parameter values.

1. Selection of high elastic EVA Block materials

The key to material selection for high-elastic EVA Block is its elasticity and durability. High-quality EVA raw materials and appropriate additives are the basis for ensuring high elasticity. When selecting raw materials, consideration needs to be given to their molecular weight distribution, crystallinity, and compatibility with other additives. In addition, it is necessary to select appropriate elastomers and tougheners to improve the material’s resilience based on the performance requirements of the final product.

2. Manufacturing process of high elastic EVA Block

The production process of high-elastic EVA Block mainly includes raw material mixing, melting and plasticizing, molding and post-processing.

In the raw material mixing stage, EVA raw materials, elastomers, tougheners, etc. are mixed evenly in a certain proportion to ensure that each component is fully dispersed. In the melting and plasticizing stage, the mixed material is fully plasticized through heating and shearing, providing appropriate fluidity and plasticity for subsequent molding processing.

In the molding process, according to the requirements of product shape and size, injection molding, extrusion or calendering are used to process the molten material into the required high elastic EVA Block. Finally, the product is completed through post-processing steps such as cooling, solidification, cutting and packaging.

3. High elastic EVA Block production process

The specific process for making high-elastic EVA Block is as follows:

Raw material preparation: Prepare EVA raw materials, elastomers, tougheners and other additives according to the formula requirements.

Mixing and stirring: Put the raw materials and additives into the mixing equipment and stir thoroughly to ensure that the components are evenly mixed.

Melt and plasticize: The mixed materials are fed into the melting equipment and heated to a certain temperature to melt and plasticize.

Molding processing: Inject the molten material into the mold or process it into high elastic EVA Block through extrusion, calendering, etc.

Cooling and solidification: Cool and solidify in the mold to make the product reach the predetermined hardness and elasticity.

Inspection and packaging: Carry out quality inspection on finished products, and then package and store them if they pass.

4. Characteristics of high elastic EVA Block

High elastic EVA Block has the following significant properties:

Excellent resilience: The material has excellent resilience and can quickly return to its original shape after being subjected to external forces.

Good durability: After special treatment, the high-elastic EVA Block has excellent wear resistance, tear resistance and aging resistance, and can maintain stable performance for a long time.

Easy to process and form: It has good plasticity and can be processed into products of different shapes and sizes through various processes such as injection molding and extrusion.

Environmental protection and safety: The materials comply with relevant environmental protection standards, do not contain harmful substances, and are harmless to the human body and the environment.

5. Application fields of high elastic EVA Block

High-elastic EVA Block is widely used in the following fields due to its excellent elasticity and durability:

Sports equipment: used to make sports shoes, yoga mats and other sports equipment, providing good cushioning and rebound effects to enhance the sports experience.

Toy industry: used to make children’s toys, such as bouncing balls, building blocks, etc., to meet children’s needs for elasticity and safety.

Packaging materials: used as buffer materials for packaging precision instruments and electronic products to prevent shock and vibration during transportation.

Auto parts: used to make car seats, steering wheels and other accessories to improve riding comfort and safety.

In summary, high-elastic EVA Block, as a material with excellent performance and easy processing, has broad application prospects in sports equipment, toy industry, packaging materials, auto parts and other fields. By rationally selecting materials, optimizing manufacturing processes and processes, and strictly controlling relevant parameter values, high-elastic EVA Block products with stable performance, safety and reliability can be produced, providing strong support for the development of various industries.