With the continuous development of material technology, multi-layer EVA Block, as a new type of composite material, has gradually become favored by the market due to its excellent physical properties and wide range of application fields. This article will introduce in detail the material selection, production process, production process, characteristics and application fields of multi-layer EVA Block, and combine it with relevant parameter values to provide readers with a true and comprehensive reference.

1. Selection of multi-layer EVA Block materials

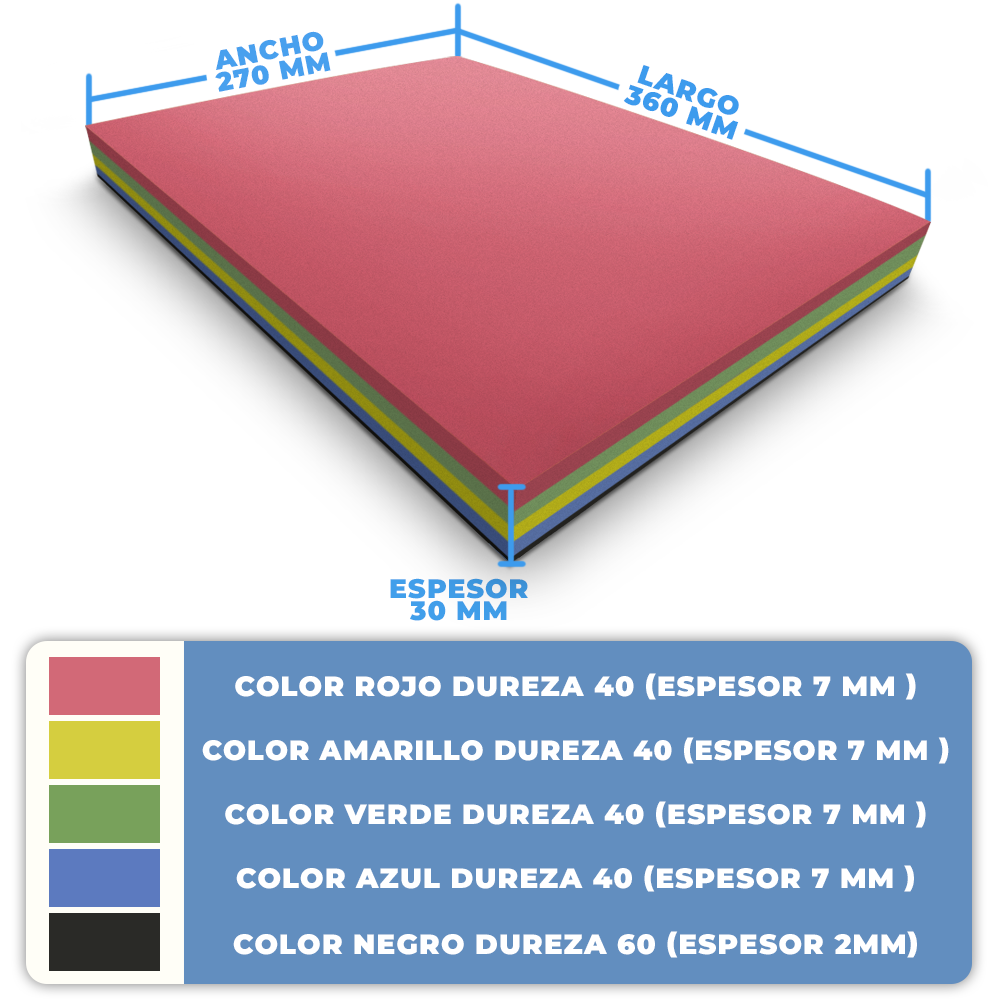

The key to material selection for multi-layer EVA Blocks lies in the compatibility between the layers and the optimization of overall performance. Typically, multi-layer EVA Block consists of EVA layers of different densities, hardnesses and elasticities, with each layer carefully selected and proportioned to achieve specific performance requirements. When selecting materials, it is necessary to consider the thickness, hardness, wear resistance, impact resistance and other physical properties of each layer, as well as the bonding strength and stability between them.

2. Manufacturing process of multi-layer EVA Block

The production process of multi-layer EVA Block is relatively complex, mainly including raw material preparation, lamination, molding and post-processing.

In the raw material preparation stage, EVA raw materials with different performance requirements need to be prepared and pre-processed according to design requirements, such as drying, crushing, etc.

In the lamination and compounding stage, professional laminating equipment is used to laminate EVA layers with different properties in accordance with the preset order and process parameters to ensure that the layers are tightly bonded to form a stable multi-layer structure.

In the molding processing stage, the laminated multi-layer EVA material is processed into the required shape and size through injection molding, calendering and other processes.

The post-processing stage includes cooling and solidification, inspection, packaging, etc. to ensure that the quality and performance of the multi-layer EVA Block meet the requirements.

3. Multi-layer EVA Block production process

The production process of multi-layer EVA Block is roughly as follows:

Raw material preparation: According to the design requirements, prepare EVA raw materials and auxiliary materials with different performance requirements.

Lamination and compounding: EVA layers with different properties are laminated and compounded in a preset order to ensure tight bonding between the layers.

Molding processing: Injection molding, calendering and other processes are used to process the laminated multi-layer EVA materials into preset shapes and sizes.

Cooling and solidification: Cooling and solidification in the mold stabilizes the multi-layer structure and achieves predetermined physical properties.

Inspection and packaging: Conduct quality inspection on the multi-layer EVA Block to ensure that it meets the design requirements before packaging and warehousing.

4. Multi-layer EVA Block characteristics

Multi-layer EVA Block has the following salient features:

Excellent physical properties: Through the design of multi-layer structure, multi-layer EVA Block combines the advantages of each layer of EVA, showing good physical properties such as hardness, wear resistance, and impact resistance.

Stable inter-layer bonding: The layers are tightly bonded through a professional lamination process, making it difficult to delaminate or peel off, ensuring the stability and durability of the multi-layer EVA Block.

Good processability: Multi-layer EVA Block retains the plasticity and processability of EVA materials and can meet the needs of different shapes and sizes.

Environmental protection and safety: The raw materials and auxiliary materials of multi-layer EVA Block comply with environmental protection standards and will not cause harm to the human body and the environment.

5. Application fields of multi-layer EVA Block

Multi-layer EVA Block is widely used in the shoe material industry due to its excellent physical properties and stable inter-layer adhesion: it is used in the midsoles and outsoles of sports shoes, casual shoes and other footwear to provide excellent cushioning and support properties.

In summary, multi-layer EVA Block, as a new type of composite material, has broad application prospects in shoe materials, packaging, construction, automobiles and other fields. By rationally selecting materials, optimizing manufacturing processes and processes, and strictly controlling relevant parameter values, multi-layer EVA Block products with stable performance, safety and reliability can be produced, providing strong support for the development of various industries.

Hot blogs:

The Easiest Custom Insoles: Heat Moldable Insoles

Custom insoles, also known as orthotic insoles, are designed to provide personalized support and comfort for individuals with various foot conditions. In [...]

Children’s Insole Size Conversion Chart

The standard sizes for shoe insoles may vary from country to country, making it a headache to choose the right insole for [...]

Do custom orthotics need to be made by a doctor personally?

Custom orthotics do not necessarily need to be made by a doctor personally. While doctors, specifically podiatrists or orthopedic specialists, are often [...]

Do NBA players use custom insoles?

Custom insoles are not only helpful for people with foot health issues, but they also play a significant role in targeting the [...]