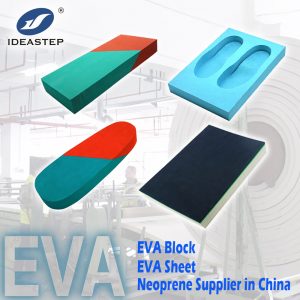

IDEASTEP Shoe material EVA midsole.

eva foam block supplier in China – Ideastep

EVA foam midsole is the most common cushioning material in modern sports shoes.

EVA foam material is used to make running shoes, basketball shoes and other sports shoes.

It has the characteristics of light weight, pressure resistance, easy coloring, easy processing and forming.

EVA foam material is the most widely used shoe midsole material.

How to make EVA foam:

EVA (ethylene-vinyl acetate), also known as PEVA (polyethylene-vinyl acetate), is a copolymer of ethylene and vinyl acetate.

Two or more monomers participate in the polymerization reaction together, and the polymer formed is called a copolymer.

In EVA, the weight percentage of VA is usually between 10% and 40%, and the rest is ethylene.

The amount of VA will greatly affect the properties of the material. High-performance EVA has a relatively high VA content, while EVA with a low VA content is hard, fragile and has poor toughness.

The EVA material can be foamed during the production process, making it an ideal choice for shoe midsoles.

EVA foaming is in the mixing process, the foaming agent is added to the EVA mixture.

Azodicarbonamide is the most commonly used blowing agent in EVA production. When heated, the solid azodicarbonamide decomposes into gas.

When trapped in the molten EVA, the gas expands to produce tiny bubbles, and finally forms a foamed material.

The appropriate hardness of the EVA midsole is between 40 degrees and 65 degrees.

Softness lower than 40 degrees will be unstable and susceptible to compression deformation, and higher than 65 degrees will not be very comfortable.

The EVA density of running, basketball and casual shoes is about 55 degrees.

EVA in footwear production

Before entering the main shoe assembly line, the midsole and outsole of the EVA shoe need to be bonded first.

This process is called bottom processing and completes the outsole assembly.

Before the bottom processing, the EVA parts are cleaned to remove the release agent, and the bonding surface can be polished to make the bonding stronger.

During the bottom processing, it may be necessary to do EVA midsole spraying, plastic heel bonding, rubber parts bonding, and adding logo.

The bottom processing line has a hot channel for drying primer and glue. This production line is very short, which may be 1/3 of the size of the main assembly line, but there will be pressure to ensure that the sole components are firmly bonded.

learn more EVA midsole , please kindly to visit our web .www.aideastep.com & www.ideastepinsole.com.

Also any other questions or suggestion , please feel free to contact us :

Tel: +86-18106960586(whatsapp)丨 Email: [email protected] /

Xiamen Kon Technology Co., Ltd

Hot blogs:

The Easiest Custom Insoles: Heat Moldable Insoles

Custom insoles, also known as orthotic insoles, are designed to provide personalized support and comfort for individuals with various foot conditions. In [...]

Children’s Insole Size Conversion Chart

The standard sizes for shoe insoles may vary from country to country, making it a headache to choose the right insole for [...]

Do custom orthotics need to be made by a doctor personally?

Custom orthotics do not necessarily need to be made by a doctor personally. While doctors, specifically podiatrists or orthopedic specialists, are often [...]

Do NBA players use custom insoles?

Custom insoles are not only helpful for people with foot health issues, but they also play a significant role in targeting the [...]