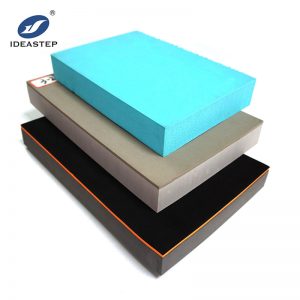

Foam material

A pair of running shoes is divided into three parts: upper (Upper), midsole (Midsole), outsole (Outsole). The midsole is the soul of running shoes, and it is also the core symbol that distinguishes major manufacturers.

The role of the midsole is to provide stability, cushioning, and rebound, absorb the impact generated during exercise and provide protection and a milder foot feel during exercise.

How to choose the rubber material formula of the midsole is very important for the whole pair of sneakers. Now the main midsole materials are EVA, TPU, POE, EDPM, and so on.

EVA foam material

One material that has revolutionized the footwear industry in the past 20 years is EVA. By foaming EVA, the sole can be made light enough, and the EVA resin with a certain elasticity can make the sole have proper cushioning function. Since then, most casual shoes and jogging shoes have adopted EVA as the sole material.

EVA foaming formula In the footwear industry, in-mold foaming generally refers to placing EVA granules into a foaming mold, and applying high temperature (160-180 degrees Celsius) and high pressure (above 150KG/square centimeter) to foam it. . In addition, there are traditional flat foam and injection foam.

EVA foaming formula is composed of lubricant (stearic acid), bridging agent (DCP), foaming agent (AC series), foaming accelerator (zinc oxide), filler (calcium carbonate) and EVA raw materials. In order to improve the physical properties of EVA products, a certain proportion of rubber (natural or artificial) will be added, and the process flow is similar to the formula without rubber.

TPU foam material as shoe material

In addition to EVA foam material, another important shoe sole material is TPU thermoplastic polyurethane elastomer. The shock-absorbing ability and durability of TPU material are stronger than EVA, but the material is heavier than EVA, and it is easy to turn yellow. In addition, it has the following three advantages:

1. The plasticity of the formula is very large, and products from the softest to the hardest can be produced by adjusting the formula;

2. Especially wear-resistant, the wear resistance is 2 times higher than that of the most wear-resistant natural rubber;

3. It can be made into very transparent or any color products.

Because TPU could not be made into microcellular foam before, it was mainly used for outsole. The usual practice is to use foamed EVA as the midsole, and then stick a thin layer of TPU on the bottom to make the outsole, so that the shoes are light and wear-resistant. But in recent years, a new type of foaming technology introduced by BASF has given TPU the possibility to comprehensively challenge the application of EVA in shoe materials. This foaming technology is also called “popcorn” (E-TPU) in the industry. It can make shoes as light as EVA. The key is to have excellent resilience, that is, to have better than EVA. Cushioning effect.

Global EVA production capacity distribution

With the development of the EVA resin industry, the global EVA resin production capacity has steadily increased, and the global EVA production capacity is mainly concentrated in Asia and North America. Among them, the countries and regions with the largest EVA production capacity mainly include mainland China, the United States, Taiwan, South Korea, and Japan. Mainland China has surpassed the United States to become the world’s largest EVA resin production area, with a production capacity of 972,000 tons/year.

my country’s EVA supply and demand

In recent years, with the vigorous development of my country’s functional shed film, packaging film, shoe material, hot melt adhesive and other industries, the demand for EVA resin products is also increasing. In 2012, the apparent consumption of EVA resin in my country was about 880,000 tons, which has increased to about 1.3 million tons in 2016 and is expected to increase to more than 1.4 million tons in 2017. From 2012 to 2017, the average annual growth rate of apparent consumption of EVA resin in my country has reached more than 10%.

Before 2008, the largest application field of EVA resin in my country was foamed products, mainly foamed shoe materials, and the consumption accounted for more than 60% of the total consumption. In 2010, the proportion of EVA resin consumption in the field of foamed products dropped to about 51%, and in 2015 it further dropped to about 45%. Emerging fields such as solar packaging materials, wires and cables, and hot melt adhesives are in a stage of vigorous development, and the proportion of consumption is rising rapidly. With the change of hot spots in the field of EVA consumption, the consumption structure of EVA resin in my country has also undergone great changes.

The Asia-Pacific region is the world’s largest TPU production and consumption area. In 2012, the output of TPU products in the Asia-Pacific region reached 249,300 tons, accounting for 58% of the global output. The output of EMEA (Europe, Middle East, Africa) and the Americas accounted for 25% of the global output respectively. and 17%.

my country’s TPU supply and demand

China is still the largest shoe-making base in Asia. From 2016 to 2017, the development of sports shoes in China has also increased, and the consumption of TPU has also increased. The competition between TPU materials and EVA, rubber and other materials is also increasingly fierce.

The growth rate of the film industry has declined in 2017, but the growth rate is still more than 10%. The industry penetration rate of TPU film is also extremely high, and it is involved in food, medical, automobile, and agriculture. Industry insiders are also more optimistic about the TPU film industry.

Although TPU consumption in the cable industry accounts for a small proportion, the better environmental recycling performance of TPU materials is also better accepted by the industry. At present, most of the TPU materials in the cable industry are monopolized by large foreign companies.

TPU 3D printing consumables have not been a dream for a long time. Several manufacturers in the industry can produce this material. The high-quality properties of TPU, such as high strength, high hardness, and a wide range of hardness, will better serve the 3D industry in the future.

TPU consumption in the shoe material industry

Although the shoe material market has shifted to Southeast Asian countries, China is still the largest shoe-making base in Asia, and most high-end shoe-making supplies are still produced in China. At the same time, the consumption of TPU materials in the shoe manufacturing industry is also gradually increasing, and it continues to occupy the market share of other rubbers.

Hot blogs:

The Easiest Custom Insoles: Heat Moldable Insoles

Custom insoles, also known as orthotic insoles, are designed to provide personalized support and comfort for individuals with various foot conditions. In [...]

Children’s Insole Size Conversion Chart

The standard sizes for shoe insoles may vary from country to country, making it a headache to choose the right insole for [...]

Do custom orthotics need to be made by a doctor personally?

Custom orthotics do not necessarily need to be made by a doctor personally. While doctors, specifically podiatrists or orthopedic specialists, are often [...]

Do NBA players use custom insoles?

Custom insoles are not only helpful for people with foot health issues, but they also play a significant role in targeting the [...]