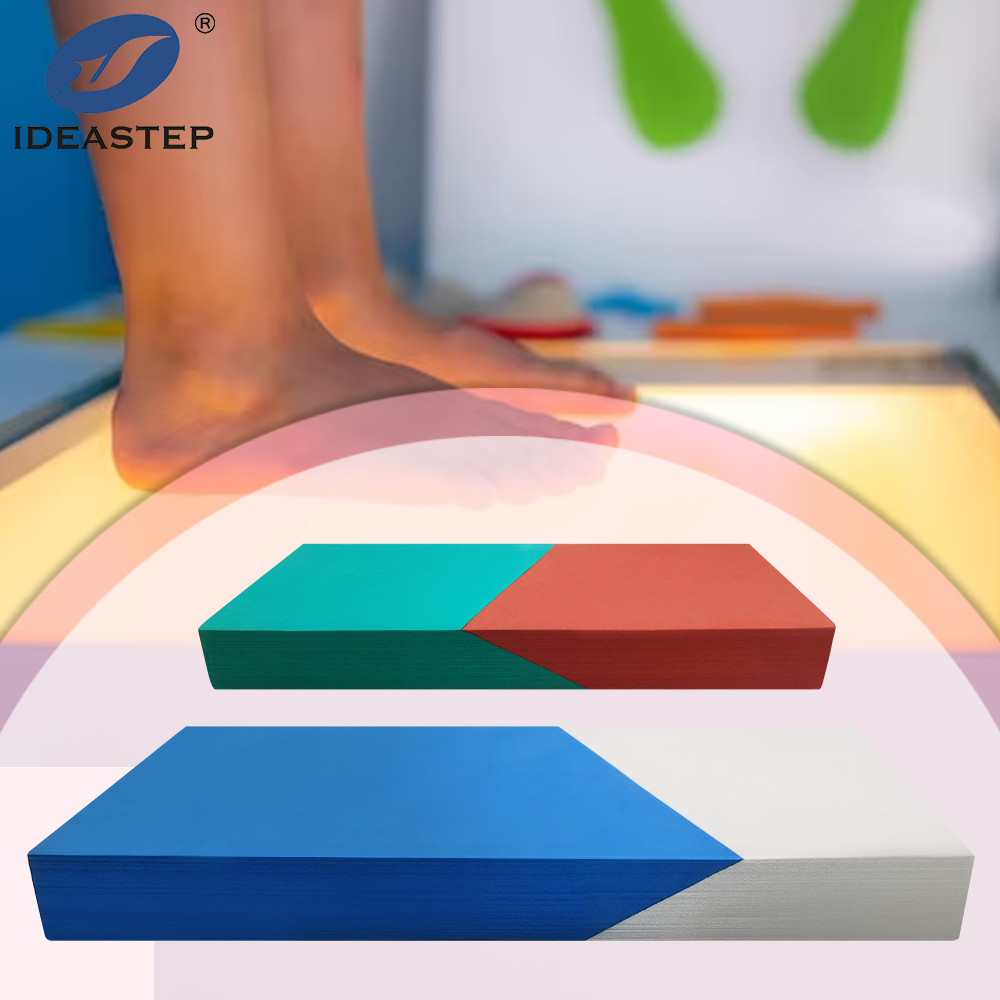

1. Application of EVA Block in running shoes

As the main material for the midsoles of entry-level running shoes, EVA Block is widely used in various brands of running shoes on the market. Its excellent elasticity and cushioning properties enable runners to get good foot feel and support during running. EVA Block can absorb ground reaction forces, reduce the impact of running on the feet, and reduce the risk of sports injuries.

However, EVA Block also has certain limitations. After long-term running use, the air in the EVA Block will gradually be squeezed out, causing the material to harden and the cushioning performance to decrease. This is also the reason why many runners feel that their feet feel stiff after using EVA midsole running shoes for a long time.

In order to solve this problem of EVA, EVA is mixed with other polymer materials, and a variety of different midsole materials are derived. Common names are these:

Nike: Cushlon, Phylon, Lunarlon

Asics: SPEVA

Mizuno: U4iC

New Balance: Fresh Foam

Brooks: MoGo, BioMoGo

Hoka: RMAT, CMEVA

Saucony: PowerGrid

Phylon

Another material related to EVA is Phylon, which is a secondary EVA foam material. During the production process, after the raw materials are injected into the mold, they are heated at high temperatures twice before being fired into shape. During the production process, the density of the material is generally controlled by controlling the temperature. The higher the firing temperature, the higher the density and hardness of the fired Phylon.

Phylon’s surface is white and wrinkled, its texture is light, its elasticity is good, and its cushioning and stability are the biggest features of Phylon. As a patented technology of Nike, most Nike basketball shoes use Phylon midsoles.

Correspondingly, due to the slightly more complicated process, the price of shoes with Phylon midsoles will also be higher.

PU

The midsole material of some shoes is made of a mixture of PU (polyurethane) and EVA. PU has the characteristics of high density and heavy weight. Its advantages are durability and strong cushioning capacity. Compared with EVA, PU has no “memory” – it is not easily deformed by stepping on and reduces the cushioning performance. The longer service life also makes it It has become a common material for the midsoles of some high-end shoes.

Based on the above content, we will introduce the application of EVA block in running shoes, and introduce the production process of EVA block and the differentiation of parameters under different situations. Introduction by subtitles

2. Manufacturing process of EVA Block

The production process of EVA Block is relatively simple. First, select EVA raw materials with appropriate density, and cut and trim the EVA raw materials according to the design requirements of the shoes to make them fit the shape and size of the midsole. Then, through the molding process, the EVA raw material is processed into the required EVA Block.

During the production process, the performance and characteristics of EVA Block can be changed by adjusting the density of raw materials, adding other polymer materials, etc. For example, increasing the density of EVA can improve its support and stability, while mixing it with other materials can improve its cushioning properties and durability.

3. Differences in EVA Block parameters under different circumstances

The performance and characteristics of EVA Block are affected by many factors. Therefore, the parameters of EVA Block will vary under different circumstances.

Density: Density is a key factor affecting the elasticity and cushioning performance of EVA Block. For running shoes that require higher cushioning performance, you can choose lower-density EVA materials to provide better foot feel and comfort. For running shoes that require stronger support, you can choose higher-density EVA materials.

Hardness: Hardness determines the pressure resistance and wear resistance of EVA Block. The stiffness of the EVA can be adjusted based on the needs of the runner and the purpose of the shoe. For example, for running shoes that need to withstand high-intensity exercise, you can choose harder EVA materials to ensure their stability and durability.

Mixing with other materials: In order to solve the problems that arise during the use of EVA materials, manufacturers often mix them with other polymer materials to improve their performance. These hybrid materials have different properties and benefits and can be selected and adapted to specific needs.

4. Summary

As the main material for running shoe midsoles, EVA Block has broad application prospects. Through reasonable production processes and parameter adjustments, running shoe midsoles that meet different needs and scenarios can be produced. However, with the advancement of technology and changing consumer needs, higher requirements have been placed on the performance and durability of EVA Block. In the future, manufacturers will need to continue to explore and innovate to meet the market’s demand for high-performance, high-quality running shoes.

Hot blogs:

The Easiest Custom Insoles: Heat Moldable Insoles

Custom insoles, also known as orthotic insoles, are designed to provide personalized support and comfort for individuals with various foot conditions. In [...]

Children’s Insole Size Conversion Chart

The standard sizes for shoe insoles may vary from country to country, making it a headache to choose the right insole for [...]

Do custom orthotics need to be made by a doctor personally?

Custom orthotics do not necessarily need to be made by a doctor personally. While doctors, specifically podiatrists or orthopedic specialists, are often [...]

Do NBA players use custom insoles?

Custom insoles are not only helpful for people with foot health issues, but they also play a significant role in targeting the [...]